CORE

It is built with thin grain-oriented silicon steel, cold-rolled, with high magnetic permeability, M0H-M3 quality, manufactured at low flow densities to provide low losses and a minimum excitation current.

It is built with thin grain-oriented silicon steel, cold-rolled, with high magnetic permeability, M0H-M3 quality, manufactured at low flow densities to provide low losses and a minimum excitation current.

Copper and/or aluminum sole plate sheet with a double insulating varnish, Kapton double fiberglass liner or electrostatic dust.

Impregnation of the assembled transformer with core and coils, in a varnish bath for 24 hours, ensuring silent operation, improves the insulation between turns and layers and protects the magnetic core from humidity.

Windings temperature increase

"Kulka" or "Clema" terminal blocks strips, brass screws or copper sole-plate depending on the capacity, placed on celaron or epoxy blocks and on the upper part of the transformer.

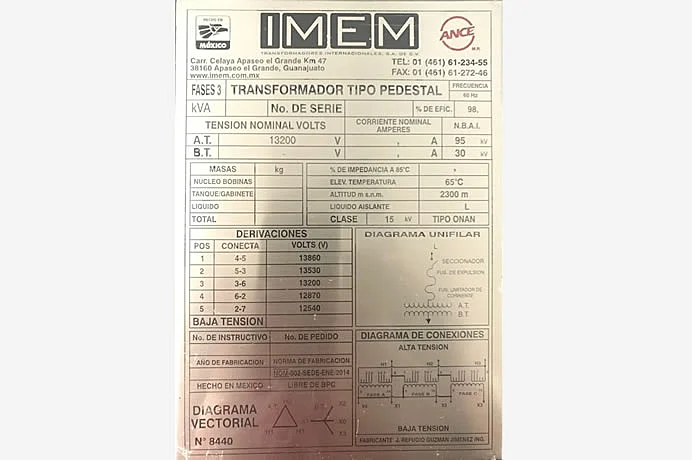

The transformer is fixed with a data plate carved in a visible part, in plastic paper for the interior service and of STAINLESS STEEL carved for weather service, with a clear identification of terminals, windings, frequency, voltage and maximum kva that will allow a safe connection.

Routine tests are carried out on each transformer to ensure compliance with customer requirements and a test report is delivered.

Turns ratio and polarity of connections.

Core losses and no-load excitation current.

Conductor losses (copper and / or aluminum) and percentage impedance calculation.

Voltage applied to the high voltage winding for 1 minute.

Between Windings and between layers the insulations are placed up to class 220ºC. According to their insulation class, these materials do not absorb moisture, do not spread flames and permanently guarantee insulation resistance between windings and to the core.

They can be supplied with enclosures types NEMA 1 indoor duty, NEMA 3 rain proof, or NEMA12 dust proof fabricated with foil. Insulation resistance with megohmmeter. Absolute guarantee.

Dry transformers have a warranty against manufacturing and material defects for one year from the date of shipment.

The dry transformers are insulated with class B, H, and / or F materials. They are prepared for work in closed environments, due to their safe operation, especially in case of fire. They are compact, maintenance-free designs.

Compared to other alternatives, they have the advantage of having a low percentage of combustible materials, reducing the emission of toxic gases (mainly CO) from steel and finished with premier and ANSI61 gray acrylic paint; or if you prefer, without a cabinet.